DPH Moule

Precision moulds for technical parts

For 30 years

DPH supports thermoplastic and rubber injection projects in

designing and manufacturing complex tooling and precision moulds, in compliance with

high quality objectives.

Design and production

Mass production moulds, pilot moulds or pre-production moulds for injectors, OEM and designers.

Precision moulds for technical parts

Moulds of 1 to 48 cavities up to 2 tonnes.

Over thirty years experience in designing and producing moulds.

Our advantages

Serving your projects

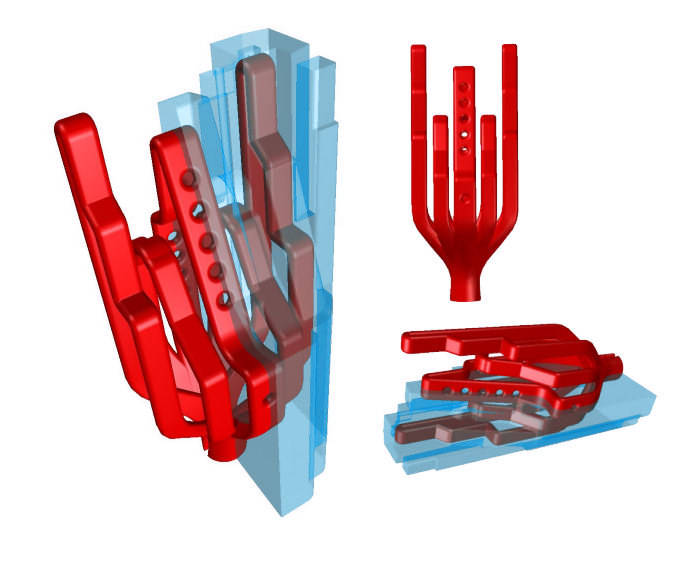

Conformal cooling

- Reduced cycle time

- Optimised reliability and quality of tools over time

Integrated design expertise

- Feasibility

- Co-design

- Part and product support

- Mould study

Resources and machine panel

- Integrated CAD/CAM

- Precision machining

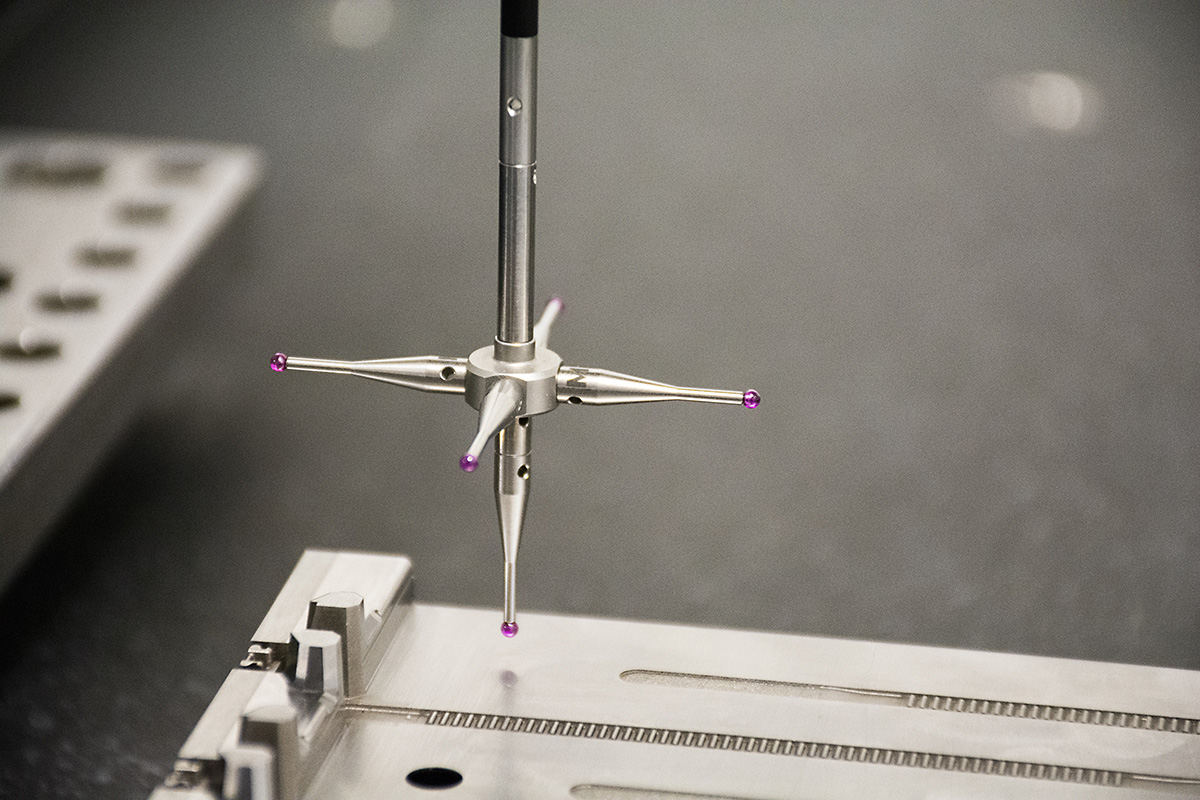

- Three-dimensional measuring machine

- Metal 3D printing

- Metrology

- Injection press testing

- Mould development and maintenance

Reactive and experienced team

Our employees

are focused on your ambitions and constraints and have many creative ideas.

Our Design Office

shows ingenuity in finding technical solutions meeting your goals.

Our processes

are adapted to the challenges of your project.

Applications

Our moulds are used in different sectors and markets:

Automotive

Find out more

Connectors

Find out more

Medical

Find out more

Electricity

Find out more

Watchmaking

Find out more

Household appliances

Find out more

Aeronautical

Find out more

Technical

Find out more